Hackensack

New Jersey

07601

United States

ASSEMBLY

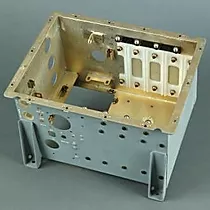

A relatively high percentage of our orders include installation of PEM nuts or mil spec hardware, marking by stenciling, silk screening or rubber stamping which is all done in our assembly department which is separately ventilated to minimize dust.

We also get requirements for bonding of card guides to exacting positional orientation or the installation of corrugated “fin material” inside walls of a heat exchanger. Parts are inspected after assembly to assure that all insert installation and all marking is present and per the drawing.

It is our intention to ship a “finished product” and we look at parts before they ship as if we were the customer receiving the parts.

Sorry, no records were found. Please adjust your search criteria and try again.

Sorry, unable to load the Maps API.