Lake Mary

Florida

32746

United States

PCB Assembly Services in FLYou are driven to exceed customer expectations, and that is only possible as your suppliers exceed your expectations.

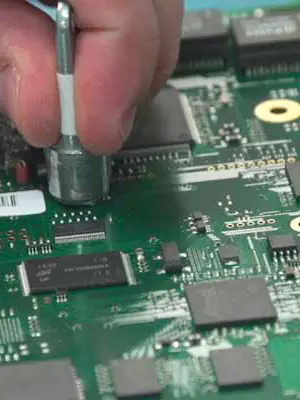

Printed Circuit Board Assembly (PCBA) or PCB Assembly, that was once a simple process of inserting leaded electronic components into a circuit board, soldering, and producing a reliable printed circuit card assembly has developed into a sophisticated, specialized science requiring only the most technically advanced professionals, the latest manufacturing technology, clearest possible communication, and a culture of commitment excellence.

PCB Assembly Services

Quality Manufacturing Services, Inc. printed circuit board assembly performance meets and exceeds whatever scope or degree of technical complexity your industry may demand. Our expertise ranges from minimal layer PCBAs with basic thru-hole component population to twenty-five layer, hidden and stacked via, impedance controlled assemblies with the latest packages in LGA, micro BGA, PQFN, and 01005 size ceramics. The QMS model has developed over years of practical experience maintaining enough organic approach to offer responsive flexibility to our customer’s dynamic printed circuit assembly requirements yet still enforcing a mechanistic, process-ownership assembly approach yielding the highest possible industry quality output.

Our professional team partners with your design and development from product inception. Design for Manufacturability (DFM) and a New Product Introduction (NPI) review are both free services QMS provides to streamline assembly and eliminate process challenges before delivery impact. Waste, inefficiency, and unnecessary cost burdens are eliminated to ensure optimal value during continuously intensifying time to market pressures and cost competition. Multiple Mydata and Panasonic SMT pick and place machines, multi-dimensional X-Ray, Electrovert Closed Loop DI wash systems, Pillarhouse selective solderers, and Yestech AOIs are just some of the advanced manufacturing systems, paired with dedicated, third-party industry accredited operating technicians, enabling our unparalleled execution.

Regardless of your industry demands or scale whether defense, commercial, or industrial, a QMS partnership enables our customers to most effectively concentrate resources and achieve the highest possible value return. Customers have enough marketplace challenges without the additional and costly burdens of program management, supply chain continuity, or insufficient quality that can compromise even the best designs. Don’t allow your reputation to settle for anything less than the very best that Quality Manufacturing Services achieves for your printed circuit assembly demands.Senior level Account Managers, technical staff, and production teams bring decades of experience to deliver an exceptional service experience and world-class product quality.

ENGINEERING

Skilled, experienced engineers develop precise processes to facilitate programs with state-of-the-art designs

MANUFACTURING

QMS utilizes best practices in the industry and continues pushing the envelope of building quality into process as well as striving for efficiency

PROGRAM MGMT

You will appreciate the value of QMS as your manufacturing partner while relying on your Program Manager to ensure success

What you need to know about

Quality Manufacturing Services, Inc.

QMS Vision Statement

Through technical excellence and superior service, with innovation, creativity and unrelenting tenacity to be the best Electronic Manufacturing Services provider in its class in the eyes of our customers, employees, and business community.

Employee-Owned, American Made

Every QMS employee is committed to delivering the highest level of service to each customer, within a culture that encourages innovation and demands continuous improvement.

Quality Excellence is Our Cultural Foundation

As an ISO-9001 registered organization, QMS epitomizes the international quality standard‘s continuous improvement impact. QMS manufactures all circuit card assemblies in accordance with the relevant customer directed J-STD-001 classification and inspects in accordance with the relevant customer directed IPC-A-610 classification.

Sorry, no records were found. Please adjust your search criteria and try again.

Sorry, unable to load the Maps API.